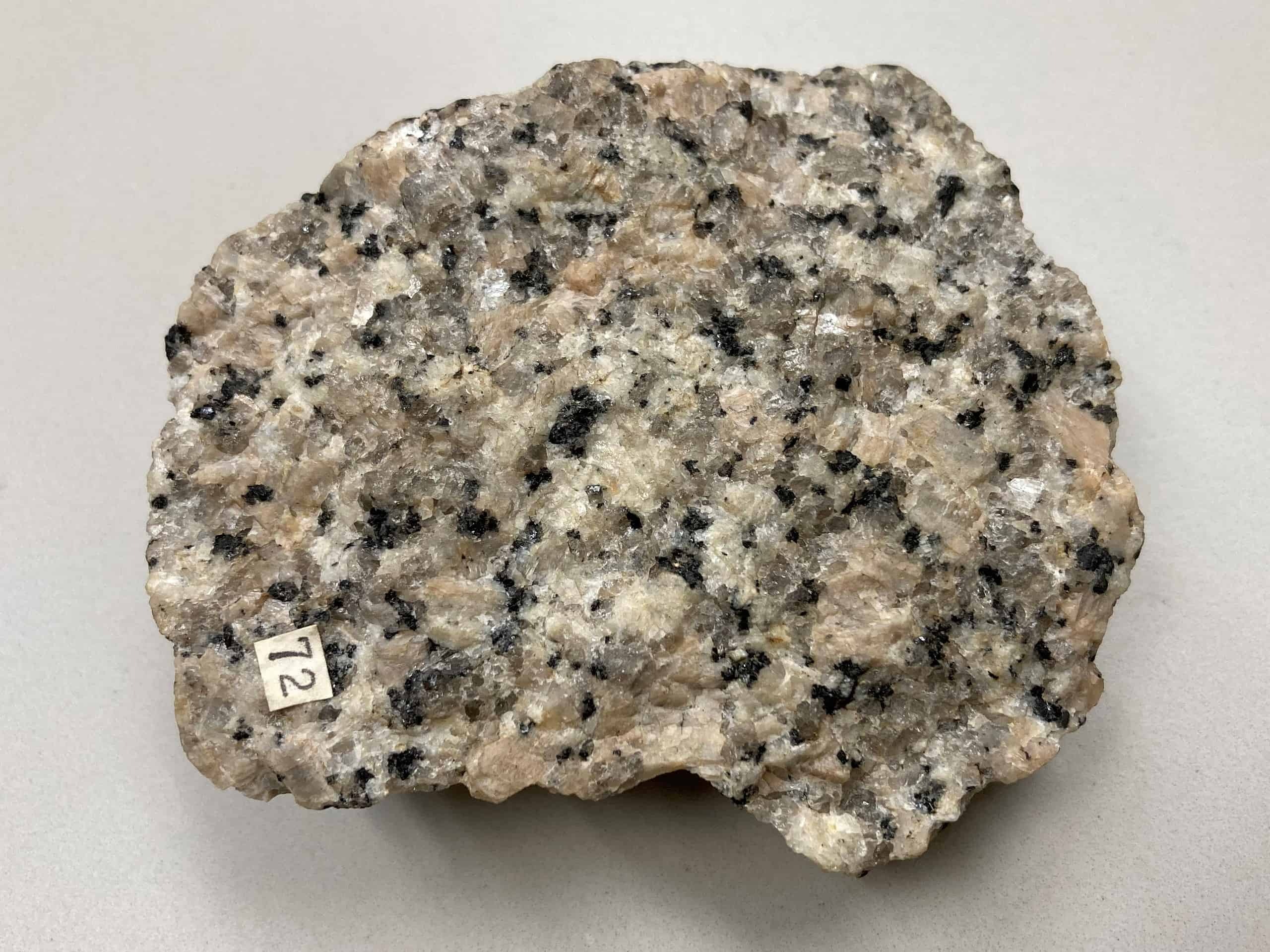

Granite is more than just a rock. It’s a foundation for timeless buildings, monuments, and landscapes. But have you ever wondered what it costs the Earth to bring this beautiful natural stone from deep inside the ground to our homes, parks, and memorials?

That question is why, at Devinarayan Granites, we don’t just focus on quality and craftsmanship—we make sustainability a priority in every step of our mining and processing journey.

Let me take you through how responsible granite production can preserve nature without compromising on beauty or strength.

Why Sustainability Matters in the Granite Industry

Mining has long been linked to land degradation, water pollution, and excessive energy use. The granite industry is no different. From drilling to cutting and polishing, the process can leave a heavy carbon footprint if not handled with care.

But things are changing. Architects, builders, and even end users are now demanding more eco-conscious materials. Granite that’s not only beautiful but also ethically and responsibly sourced.

Sustainable granite mining isn’t just good for the environment—it’s also good business. It creates long-term value, builds trust, and sets a new standard in the natural stone market.

The Granite Lifecycle: From Earth to Elegance

To understand sustainable practices, we first need to look at how granite goes from a quarry to a finished product.

- Extraction – Large granite blocks are extracted from quarries using drilling and controlled blasting.

- Processing – These blocks are then cut into slabs, tiles, or monuments using gang saws, wire saws, or CNC machines.

- Finishing – Surfaces are polished, flamed, honed, or leathered to suit various applications.

- Export & Installation – Finished products are crated, shipped, and installed across the globe.

Each stage presents its own environmental challenges—energy use, dust, water consumption, and material waste. That’s where smart, sustainable practices come in.

Responsible Quarrying: Devinarayan’s Green Footprint

At Devinarayan Granites, we operate our own quarries—like Vizag Blue, Paradiso, and Indian Juparana—which gives us full control over how granite is extracted. Here’s how we do it better:

- Controlled Blasting – We avoid excessive force. Instead, we use low-impact explosives to reduce vibration, dust, and damage to surrounding rock.

- Bench Mining Techniques – Our step-by-step extraction keeps the quarry safe and minimizes erosion.

- Minimal Overburden Removal – We only clear what’s necessary, protecting native vegetation and soil.

We also restore quarry sites after mining is completed—either by turning them into water reservoirs, green zones, or usable landscapes.

Eco-Friendly Granite Processing: Clean Cuts, Less Waste

Granite processing is where a lot of environmental strain happens—especially with electricity and water. That’s why our manufacturing units are designed to reduce our carbon footprint:

- Water Recycling Systems – Granite cutting needs water to cool blades. Instead of wasting it, we collect, filter, and reuse it in a closed-loop system.

- Dust Extraction Units – To keep the air clean, we use modern filtration to trap silica dust and airborne particles.

- Low-Emission Machinery – Our polishers, grinders, and cutters are energy-efficient and maintained regularly to reduce energy drain.

Plus, our ISO-certified processes help us stay compliant with international environmental standards and ensure continual improvement.

Zero-Waste Thinking: Turning Scraps into Products

Most granite processing plants produce tons of waste—broken tiles, irregular slabs, leftover blocks. We see those not as waste, but as opportunities.

Here’s how we reduce and repurpose:

- Rock Pitched Naturals – These rustic monuments, popular in Iceland and Canada, are crafted from uneven offcuts.

- Turned Stones – Vases, urns, and candle holders are shaped from leftover cores.

- Granite Furniture – Benches, garden tables, and even outdoor fireplaces are made from surplus slabs and edge trimmings.

This not only reduces landfill load but also offers our customers unique, one-of-a-kind products.

Packaging and Shipping: Thinking Beyond the Quarry

Shipping stone across oceans isn’t exactly light work. But even here, we try to make smarter choices:

- Eco-Friendly Crating – We use sustainably sourced wood and reusable metal frames for crating.

- Optimized Container Loading – Advanced 3D modeling helps us load more efficiently, reducing fuel use and emissions.

- Global Compliance – Whether shipping to Europe, Australia, or North America, we follow all international environmental and packaging standards.

And yes, every shipment includes full documentation and traceability. Our customers always know where their stone came from—and how it got there.

Trust Built on Certifications and Memberships

Being sustainable isn’t just about actions—it’s about accountability. That’s why we’re proud members of:

- Capexil

- FIGSI (Federation of Indian Granite and Stone Industry)

- TNGQOEA

We’re also ISO-certified, which means every part of our process—from quarry to crate—is audited for safety, quality, and environmental care.

Educating Clients: The Future is Ethical Stone

Today’s buyers want more than just stone—they want stories, transparency, and assurance. That’s why we help our B2B clients understand the green side of granite.

Whether it’s a monument designer in Germany or a landscaping architect in the USA, we help them:

- Choose sustainable finishes like leathered or flamed (which use less polish).

- Match their projects with LEED and green building standards.

- Promote eco-certification and origin tracing on their own marketing materials.

The Road Ahead: Innovation + Responsibility

Sustainable granite mining isn’t a destination—it’s a journey. At Devinarayan Granites, we’re constantly exploring:

- Solar-powered processing units

- Rainwater harvesting at quarries

- AI-based cutting optimization to reduce errors and waste

As demand grows for ethically sourced building materials, we’re proud to lead by example. Because every slab of granite should not only stand the test of time—but also respect the land it came from.

Want to know more about our granite or our sustainability efforts?

Visit Devinarayan Granites and explore how we blend tradition with responsibility, one block at a time.